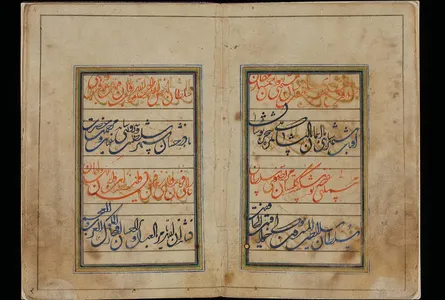

The secret of making paper has been known since ancient times. The first paper was made in China and the secret of manufacturing was kept in the strictest confidence until the 8th century.

The legend says that when the Chinese troops invaded the territory of the Samarkand ruler Abu Muslim in the mid-8th century, the Samarkand troops put up fierce resistance to the invaders and defeated the foreigners. During the battle, many Chinese prisoners were captured, among whom were paper craftsmen. In exchange for their lives, they agreed to reveal the secret and set up paper production in Samarkand. From that moment until the 18th century, Samarkand became the Central Asian center for the production of mulberry-tree bark paper.

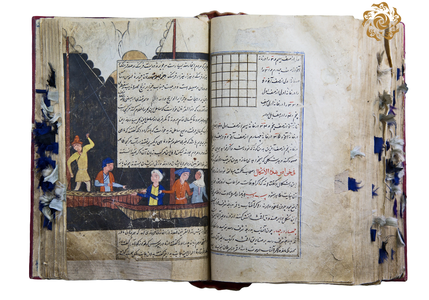

It is surprising that the centuries-old traditions of making this legendary paper have been preserved; now it is produced in the tourist village of Konigil, at the Meros paper factory located 13 kilometers from Samarkand. It was founded by the artisans Mukhtarovs brothers. Thanks to them, the factory was revived and established the production of paper in the ancient way; the technology was used long before the advent of paper machines. The main feature of this technology is manual labor, in which only natural raw materials are used. An ordinary sheet can be stored for 40 years and Samarkand paper is ten times longer - 400 years.

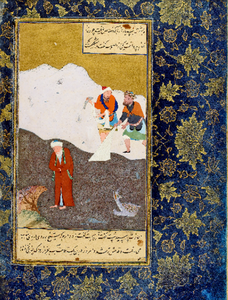

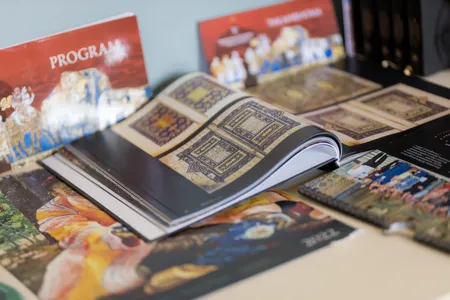

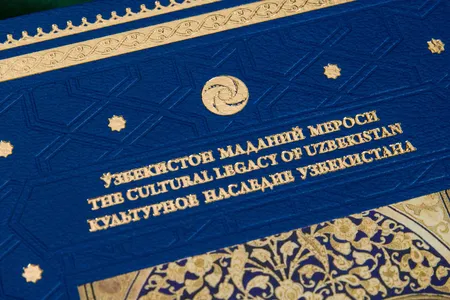

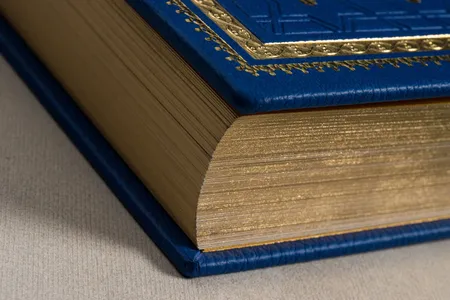

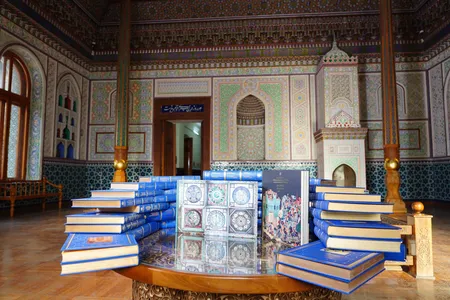

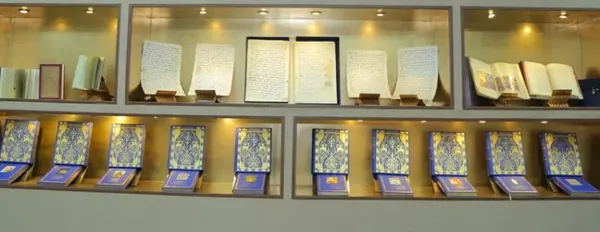

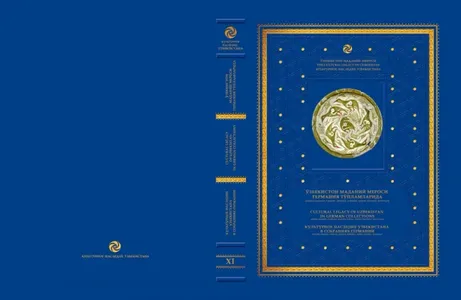

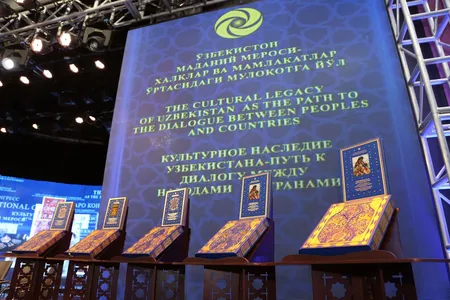

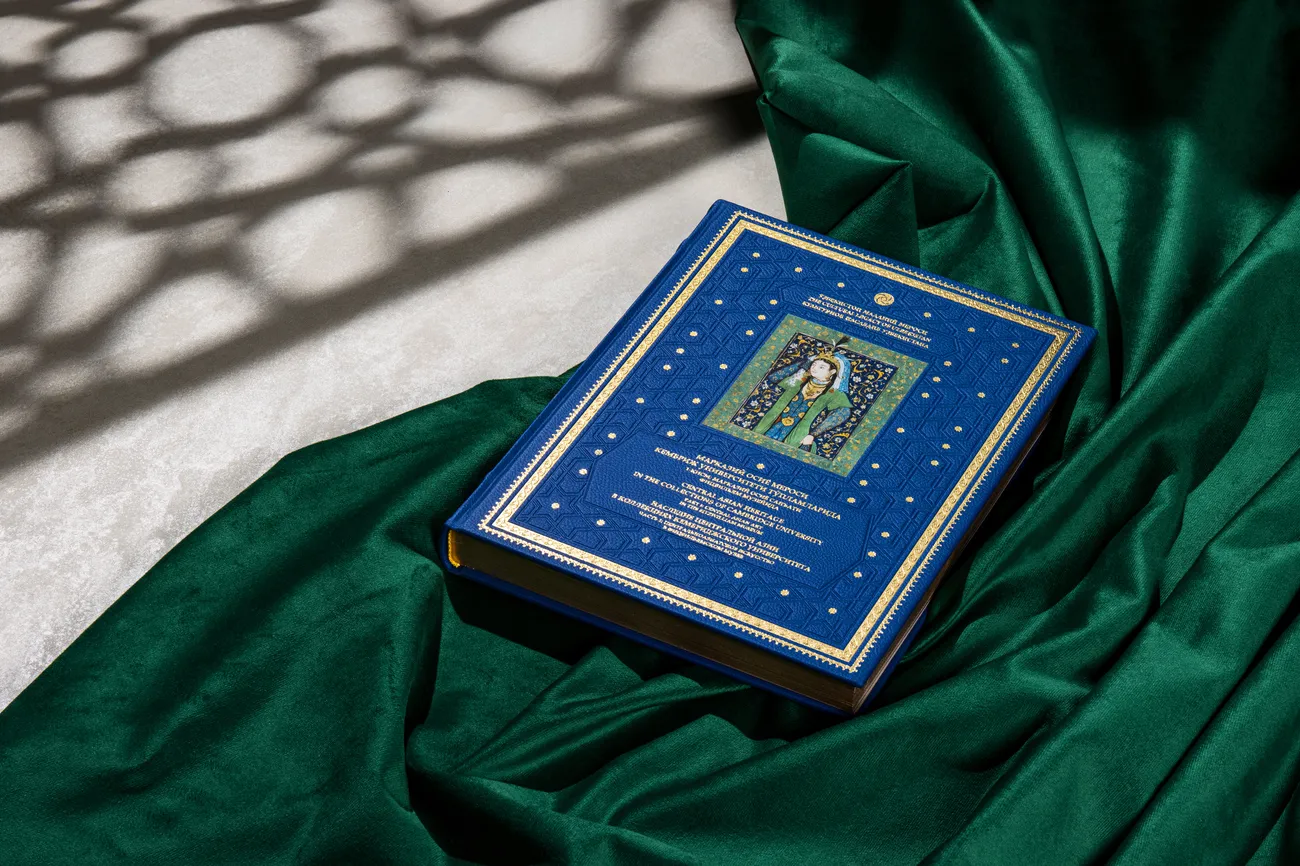

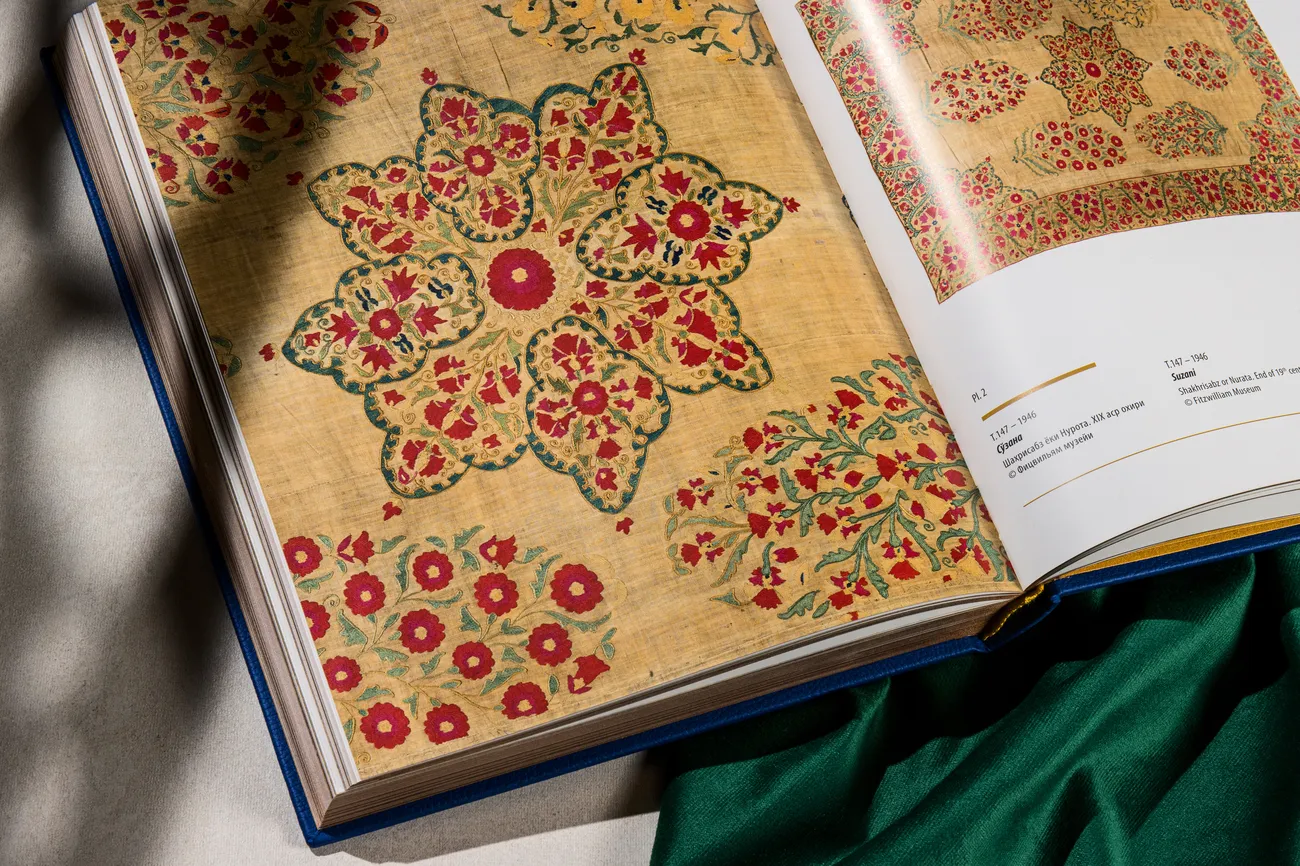

For the blue books from the Cultural Legacy of Uzbekistan in the World Collections series, matte coated paper is used, which is produced in Finland. 1 square meter of such paper weighs 135 grams.

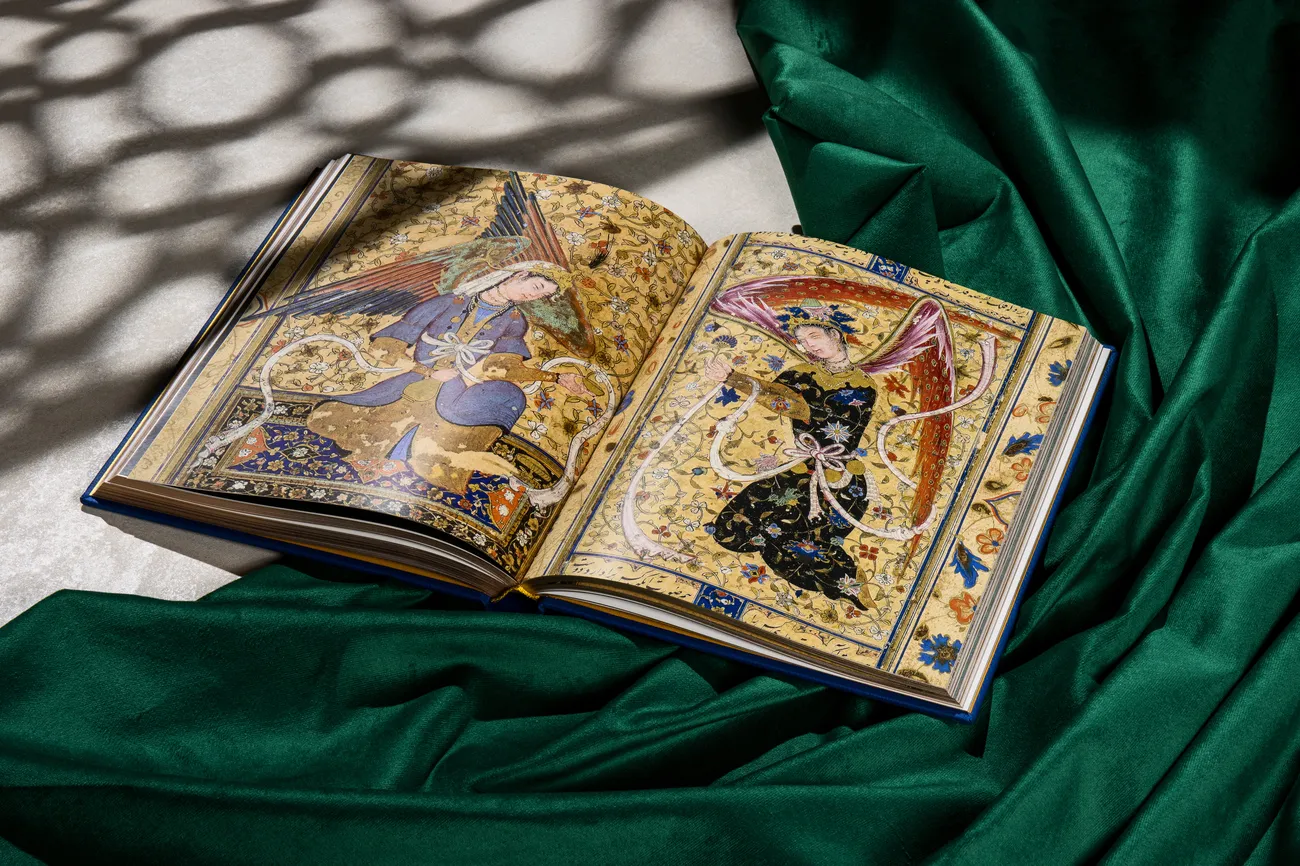

The name is due to the fact that coated is a special layer that is applied to the paper base and does not allow paints to soak into the paper and spread. The ink dries quickly, the bleeding of the printed element is reduced, and due to this, the image becomes brighter and more attractive than on offset paper. The whiteness of the paper can reach 98% due to the coated layer.

Coated paper is characterized by density, strength and low absorbency. It is used wherever the presentability of the appearance of printed products is important. As a rule, this paper is denser than other varieties, and its price is higher, for example, offset.

How is it that the paper of our books is matte, but the pages are shiny? The glossy effect is already achieved during printing. A special varnish is applied to the sheet, giving the page a light, pleasant sheen. This is a protective dispersion varnish that protects the pages from damage and scratches.

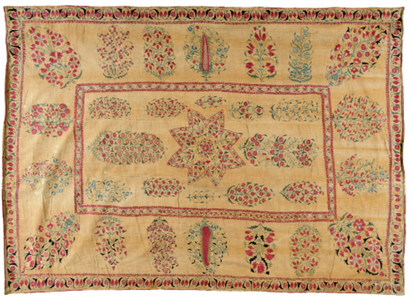

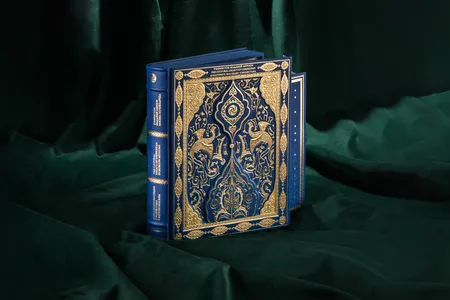

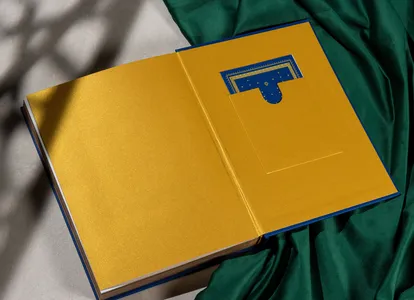

For the front and back endpapers, a special design paper of a golden hue is used, which is made from the finest cellulose fibers. This is a premium type of paper that has a special texture or embossing, various types of coatings to give the product a non-standard visual and tactile sensation.